In-line Autonomous Inspection for smart manufacturing

(Precision-Type; Auto-Type; Desktop-Type)

In-line autonomous inspection on the shop floor.

The measuring data are automatically saved into a databank which connects with the customer’s ERP/MES system. It has the advantages of real-time monitoring of the quality and shortening the response time of error correction in production.

Background of the Application

The in-process inspection includes sampling inspection and on-site autonomous inspection. Usually, the sampling inspection is performed in the laboratory and the measurement results came out after a period of time. Although in-line autonomous inspections are relatively instantaneous, the measurement items are very few because only traditional measuring tools available. Moreover, the measurement results vary from person to person. It results in poor measurement reproducibility and causes ineffective control of production quality in real-time. Anyway, in-line autonomous inspection will be the trend of industry development.

Solution

All TIMI-series image measuring instruments are suitable for decentralized in-line autonomous inspection. The measurement items can be set separately for the different manufacturing processes. Not only can effectively shorten the inspection time, but also complete the full-dimension inspection.

Features

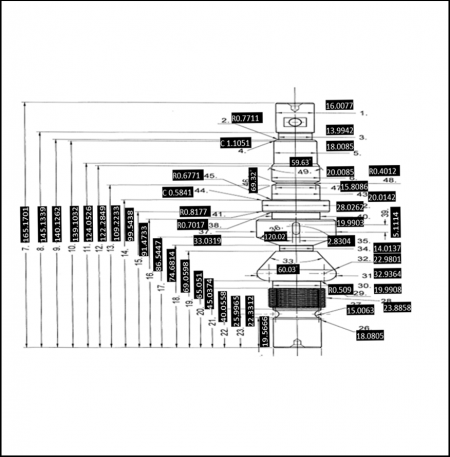

Measure the full dimensions with a one-button enabled script. And the measuring data will be automatically saved in the databank.

Real-time statistical process control for autonomous inspection, and show the X_bar和R chart in line.

Benefits

Over years, the tools used for in-line autonomous inspection are limited. After introducing TIMI-series measuring machines, the inspection items are increased, but manpower is saved than before. Our customers stated that all the inspection is valid since using the TIMI-series machines. Based on the real-time inspection data, operators can view the Ẋ and R chart anytime. It is significant to shorten the response time of error correction and prevent waste production.

- Measurment Application

-

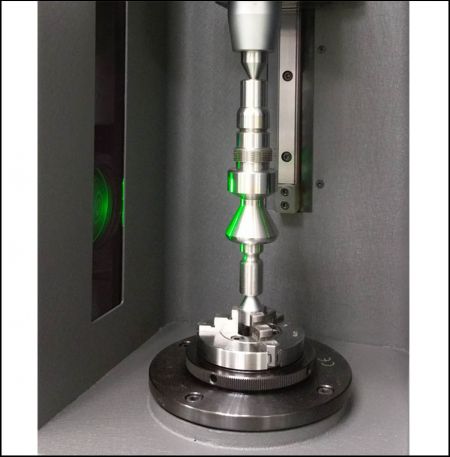

Precision-Type Telecentric Image Measuring Machine

It is ideal for measuring the shafts with a high degree of precision, or the lengthy turned and ground shafts. (TIMI 60P, TIMI 40P,TIMI 30P)

Precision-type Image Measuring Machines are ideal for inspecting high-precision CNC turned...

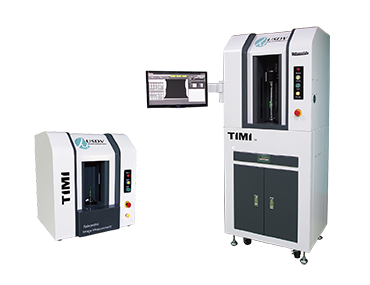

DetailsAuto-Type Image Measuring Machine

Auto-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Auto-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

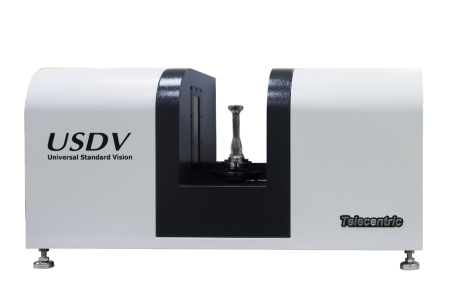

DetailsDesktop Image Measuring Machine

Desktop Image Inspection Machine is suitable for measuring shaft, screw and cylindrical parts: outer dia ≦ 60mm, length ≦ 100mm or outer dia ≦ 60mm, length ≦ 200mm (TIMI 12F, TIMI 30F, TIMI40F,TIMI60F)

The Desktop telecentric image measurer/inspector is a desktop model with a high-end measurement...

Details