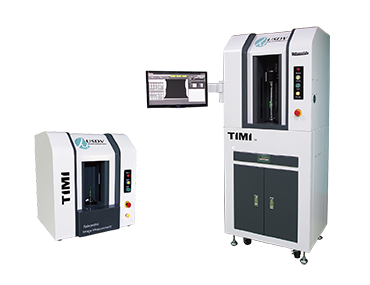

Precision-Type Telecentric Image Measuring Machine

It is ideal for measuring the shafts with a high degree of precision, or the lengthy turned and ground shafts. (TIMI 60P, TIMI 40P,TIMI 30P)

Precision-type Image Measuring Machines are ideal for inspecting high-precision CNC turned parts such as automotive transmission shafts.

With upper and lower center tips on both ends, it will produce a more precise measurement result. In addition, a precise collet can be used in place of the lower center tip. Ultra-telecentric image technology is also incorporated to enhance the measuring precision.

Application

1. Precisely measure the dimensions of machining shafts of CNC machining /cylindrical grinders: transmission shafts/camshafts/various spindles

2. Maximum measuring diameter: 100 mm / 40 mm / 30 mm

3. Maximum measuring length: 300 mm / 600 mm

4. Incoming material inspection/first article inspection/in-process inspection/final inspection

Features and Benefits

1. The CNC shaft measurement is more precise because the shaft is held by the double-sided center-tips.

2. Automatically measure more than 30 dimensions of a 300 mm long shaft in less than 40 seconds.

3. The radial measuring uncertainty is ±(2+ D / 100) μm, and the measured value can be used to compensate machining parameters.

4. It can resolve the Grinding Diameter Difference up to 1μm.

5. The measuring uncertainty for the plug gauge's pitch diameter is only ±3μm.

6. The precision-machined arc radius has a measuring uncertainty of only ± 5μm.

7. Automatically analyze the center coordinate of a shaft and reconstruct the radial profile.

8. Measure the roundness, cylindricity, concentricity and run-out in a vertical rotation based on the central axis coordinate.

9. The user-friendly interface allows you to quickly select an image area and measure it.

10. Measuring data can be automatically stored in a databank and linked to a client's ERP/MES/SPC system.

Image Measurement Machine Product Specification

| MODEL/TYPE | TIMI60P Cabinet | TIMI40P Cabinet | TIMI30P Cabinet |

|---|---|---|---|

| Measurable Width | 60mm | 40mm | 30mm |

| Measurable Length | 300mm~600mm | 300mm~600mm | 300mm |

| Image Resolution | 19μm | 19μm | 14μm |

| Repeatability Accuracy | ± 0.3μm | ± 0.3μm | ± 0.2mm |

| Precision (± 2σ) | ± 3μm | ± 2.5μm | ± 2μm |

| Rotational Axis Resolution | ≦ 0.1° | ≦ 0.1° | ≦ 0.1° |

| Lifting Mechanism Resolution | 1μm | 1μm | 1μm |

| Clamping Method | double-sided tips | double-sided tips | double-sided tips |

| Max. Part Weight | 10kgs | 8 kgs | 8 kgs |

| Machine Weight | 450 kgs | 350 kgs | 280 kgs |

| Reference Size | 1200mm (W) x 800mm (D) x 2190mm (H) | 890mm (W) x 720mm (D) x 1880mm (H) | 880mm (W) x 720mm (D) x 1880mm (H) |

| Power Supply | Single-phase 110V, 10A /220V, 10A | ||

* Precision is estimated as ± 2σ by measuring original standard gauge.

* Machine operating temperature: available for 0°~ 45° environment.

Applicable Industry

■ Automobile, motorcycle, bicycle, ATV and other vehicles industry

■ Aerospace industry

■ Electrical / electronic industry

■ Information and Communication Industry

■ Electric / air tool industry

■ Medical equipment industry

■ CNC Turned Parts / Grinding Processing Industry

- Download

- Video