Measurement of Motor Spindle

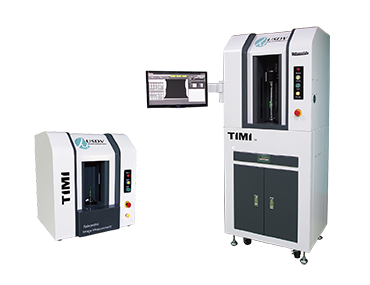

(Precision-Type: TIMI 30P/ 40P ; Auto-Type: TIMI 30A/ 40A)

Automatically measure full- dimensions in 20 seconds.

TIMI-series automatically measure full- dimensions in 20 seconds. Measurement results are automatically recorded, greatly reducing the workload and error of manual handwriting, promoting production efficiency.

Background of the Application

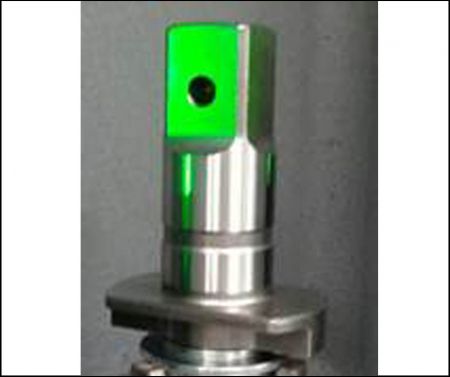

Machinery spindles such as those of motors and power tools are high-speed rotating shafts. The main measurement items are physical dimensions and coaxiality tolerance. For mass production, the use of manual measuring tools in the past often required more manpower, and only a few key appearance dimensions could be inspected.

Solution

TIMI 30P and 40P precision type image measuring instruments are very suitable for the measurement of longer spindles like motor spindles. TIMI 30A and 40A can be used to measure shorter spindles like those of power tools.

Features

TIMI-series automatically measure full- dimensions in 20 seconds.

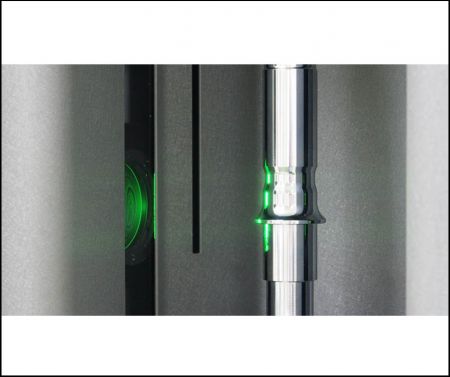

Automatically measure coaxiality by selecting any two positions along the axis.

Benefits

For incoming or in-process inspection, only less than 5 physical dimensions can be checked every 30 seconds. But TIMI-series system can check more than 15 items at the same time, including the coaxiality. Further, Measurement data is recorded automatically, which saves labor more.

- Measurment Application

-

Precision-Type Telecentric Image Measuring Machine

It is ideal for measuring the shafts with a high degree of precision, or the lengthy turned and ground shafts. (TIMI 60P, TIMI 40P,TIMI 30P)

Precision-type Image Measuring Machines are ideal for inspecting high-precision CNC turned...

DetailsAuto-Type Image Measuring Machine

Auto-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Auto-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

Details