Automatic Image Measurement – Complete Full-Dimension Inspection in Seconds + Accurate, Fast, and Intelligent Measurement Solutions

Products

Optical Measurement Experts|Smart Solutions for Shaft & Thread Inspect

USD Vision specializes in non-contact precision dimensional image measurement technology, providing one-stop solutions for shaft parts, screws, bolts, and other cylindrical workpieces. It meets the growing demand for full-scale, fast, and high-accuracy inspections directly on the shop floor.

Key challenges: Are you facing the following issues when process the measurement on the shop floor?

- Low efficiency and high operator dependency when using calipers or projectors?

- Complex dimension and tolerance checks require multiple measuring tools?

- Critical dimensions remain difficult and inconsistent to measure?

- Traditionally, measurement data cannot be save in real-time , making statistical analysis and traceability difficult?

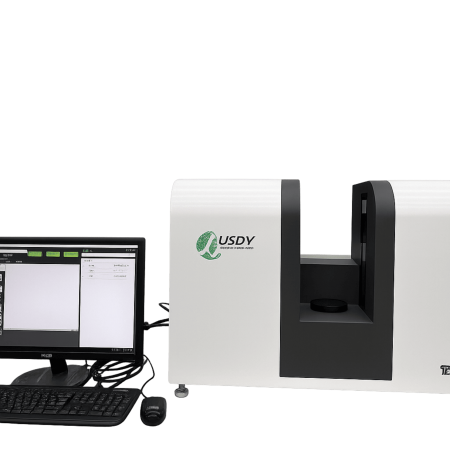

TIMI Fully Automatic Image Measuring System – Your Complete Solution

•One-click measurement of multiple dimensions and geometric tolerances, with objective and traceable data.

•Non-contact high-precision measurement, full-dimension inspection in seconds, reducing manpower dependence and shortening average measurement time by 70%.

•Rotational positioning and intelligent algorithms support advanced inspection needs such as high-grade threads, precision shafts, and turn-mill complex parts.

•Built-in database and reporting functions connect to ERP / MES / SPC, supporting continuous improvement and realizing smart manufacturing.

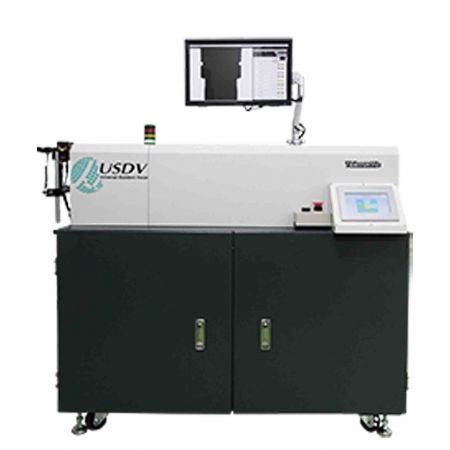

High-speed metrology system designed for shop-floor deployment

- Rotational auto-positioning measurement with intelligent algorithms: Automatic alignment and frame selection for intuitive operation.

- High-resolution non-contact image measurement: Achieves micron-level accuracy, replacing CMMs and profilometers.

- Modular script switching: Supports multi-model automated switching and batch inspections.

- Real-time data storage and SPC analysis: PDF / Excel report export, SPC charts, Cpk process capability analysis, and production traceability.

- Ideal for shop-floor integration: Easily integrates with robotic arms or conveyor systems.