CASES

Automated Measurement Solutions

Enabling Intelligent Quality Management Through Automated Measurement

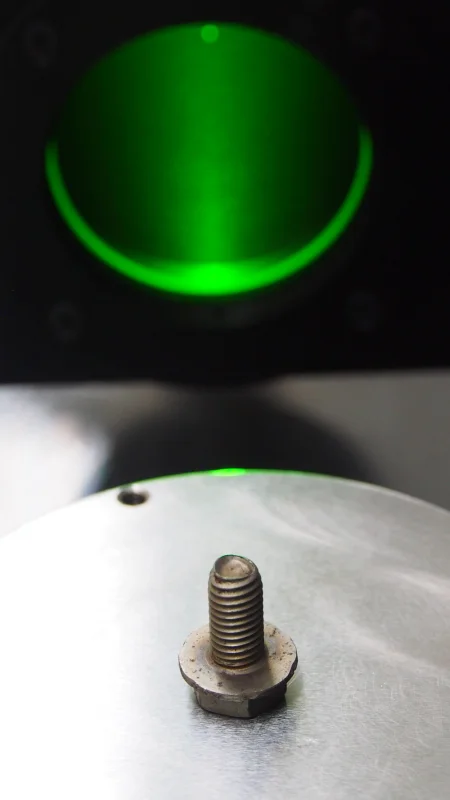

Precision and consistency are vital in modern manufacturing, especially when inspecting shafts and cylindrical components. USDV’s TIMI series delivers a fully automated optical measurement system designed to perform dimensional and geometric inspections at micron-level accuracy in the floor shop.

Equipped with advanced telecentric optics and patented imaging algorithms, TIMI systems dramatically reduce inspection times while improving accuracy and repeatability. Users can automatically inspect key parameters such as roundness, coaxiality, runout, and thread geometry—within seconds. Data can be instantly saved or uploaded to MES or SPC systems, enabling real-time traceability and quality visualization.

Key Features

- High-speed, high-precision measurement for shafts, threads, and cylindrical parts

- Covers over 70% of traditional inspection items (e.g., CMM, gauges)

- Up to 90% reduction in inspection time

- available MES/SPC data integration

- Supports fully automated workflows with robotic arms and conveyors

Return on Investment

By replacing manual gauges and multiple tools, TIMI systems shorten inspection from 10–30 minutes to under 3 minutes for most parts. With a payback period of 6–8 months, manufacturers benefit from improved process control, reduced scrap, and enhanced compliance with customer standards.

Expert Support

USDV provides end-to-end consulting, from script creation to report analysis and system integration. Whether for new production lines or upgrades to existing QC processes, TIMI offers manufacturers a scalable and smart solution to meet rising quality demands.

Thread Plug Gauge Automatic Measurement

S Company, a global leader in high-end bicycle components, ranks among the top private-label...

Read moreOn-Line Driveshaft Solution

DONGHA, a well-known driveshaft manufacturer in South Korea, previously purchased a high-end...

Read moreFull Inspection of Camshaft Dimensions

Camshafts are critical components influencing mechanical performance. In the past, traditional...

Read moreSmart Inspection of Tri-Lobular Screws

Tri-lobular screws are widely used in home appliances, electronics, and automotive applications....

Read more