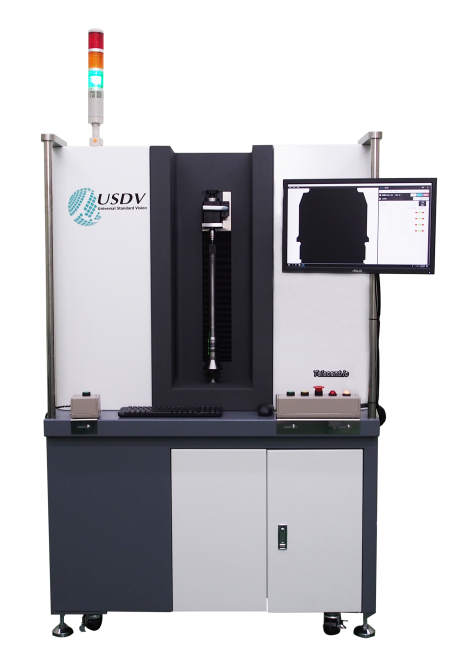

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision? Our Precision Telecentric Image Measuring/Inspection Instruments are the perfect fit. Designed for high-precision measurement tasks, these instruments are ideal for shafts like vehicle drive shafts, camshafts, and similar components.

Key Applications

1.Precision CNC Lathe and Cylindrical Grinding Shafts: Accurately measure drive shafts, camshafts, and various spindles.

2.Measurable Shaft Sizes: Maximum diameter options are 60 mm, 40 mm, or 30 mm, with lengths up to 300mm, 450mm,600mm and 900 mm.

3.Versatile Inspection Phases: Ideal for incoming inspection, first article inspection, in-process inspection, and final inspection.

Product Features

1.Dual-Center Clamping System: Upper and lower center-tips securely hold the shaft for precise results by its center holes, with a precision collet option for shafts without center holes.

2.Fast and Precise Measurement: Automatically measures over 20 dimensions on a 300 mm long shaft in just 40 seconds, improving inspection speed and efficiency.

3.High-Precision Measurements: Achieves radial measurement uncertainty of ± (2 + D / 100) μm, suitable for tool compensation and resolving grinding diameter differences down to 1 μm.

4.Advanced Dimensional Accuracy: Delivers gauge pitch diameter measurement uncertainty of ±3 μm and arc radius uncertainty of ±5 μm for precision-machined parts.

5.Comprehensive Rotational Measurement: Automatically finds shaft center coordinates and reconstructs the radial profile for precise analysis of roundness, cylindricity, coaxiality, and concentricity.

6.Real-Time Results and Data Integration: The "Measure as You Frame" feature delivers real-time measurement data through an intuitive interface, automatically saving results to your database with integration into ERP, MES, and SPC systems.

Our precision telecentric image measuring instruments offer the accuracy and efficiency you need for high-precision shaft inspection in industries like automotive, aerospace, and precision manufacturing.

Product Specification

| MODEL/TYPE | TIMI60P Centering | TIMI40P Centering | TIMI30P Centering |

|---|---|---|---|

| Measurable Width | 60mm | 40mm | 30mm |

| Measurable Length | 300mm,450mm,600mm,900mm | 300mm,450mm,600mm | 300mm |

| Image Resolution | 19μm | 19μm | 14μm |

| Repeatability Accuracy | ± 0.3μm | ± 0.3μm | ± 0.2mm |

| Precision (± 2σ) | ± 3μm | ± 2.5μm | ± 2μm |

| Rotational Axis Resolution | ≦ 0.1° | ≦ 0.1° | ≦ 0.1° |

| Lifting Mechanism Resolution | 1μm | 1μm | 1μm |

| Clamping Method | double-sided center clamping | double-sided center clamping | double-sided center clamping |

| Max. Part Weight | 10kgs | 8 kgs | 8 kgs |

| Machine Weight | 500 kgs - 750 kgs | 350 kgs - 550 kgs | 350 kgs |

| Reference Size | 1200mm (W) x 800mm (D) x 1800mm (H) | 890mm (W) x 720mm (D) x 1800mm (H) | 880mm (W) x 720mm (D) x 1800mm (H) |

| Power Supply | Single-phase 110V, 10A /220V, 10A | ||

* Precision is estimated as ± 2σ by measuring original standard gauge.

* Machine operating temperature: available for 0°~ 45° environment.

Applicable Industry

■ Automobile, motorcycle, bicycle, ATV and other vehicles industry

■ Aerospace industry

■ Electrical / electronic industry

■ Information and Communication Industry

■ Electric / air tool industry

■ Medical equipment industry

■ CNC Turned Parts / Grinding Processing Industry

- Measurment Application

Measurement of Automobile Transmission Shaft

( Centering-Type: TIMI_P)

The Precision-type Measuring Machine is perfect for the transmission shaft measurement of outer...

Details- Video