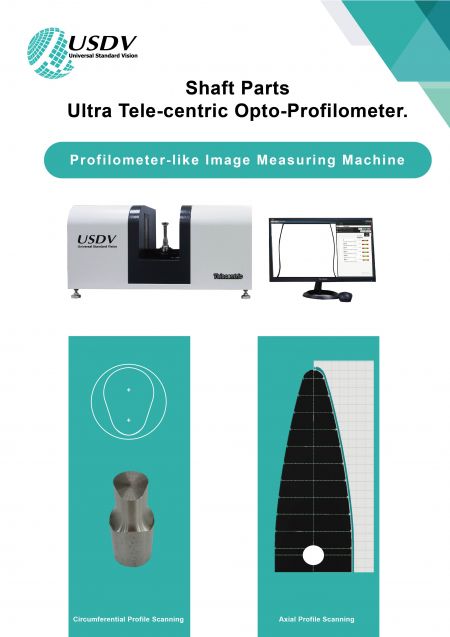

Telecentric Opto-Profilometer for Shaft Parts

A image dimension measurement instrument that can be used as a profile projector

This machine has a measurement precision of microns and can perform multiple functions of various conventional gauges at the same time, especially having the capability of scanning profiles in both circumferential and axial directions simultaneously.

In addition to manual measuring instruments such as calipers and micrometers used on production lines, laboratories also use digital instruments such as 3D, projector, 2.5D image measurement instruments, and profile projectors to measure shaft dimensions. Typically, users must use multiple instruments to complete all the dimensional measurements of a shaft, which is not only time-consuming but also costly in terms of investment in measurement equipment. This profile measurement instrument can be used on production lines as well as in laboratories, providing an economical and complete solution.

Measurement Functions

Shaft outer diameter, R angle, chamfer, included angle, segment height, thread, inner diameter of shaft side through-hole, width of shaft side opposite, rotation angle of shaft side, straightness, verticality, parallelism, roundness, cylindricity, coaxiality, circular runout, and profile.

Product Features

• The machine has both circumferential and axial profile scanning capabilities.

• The circumferential scanning resolution is 0.018°.

• The axial scanning resolution is 0.001mm.

• Automatically scan the shaft profile, easy to operate, faster measurement speed, and lower maintenance costs, more suitable for measuring large shafts with high precision requirements.

• Reconstruct the 2D profile of the shaft and compare the profile with the CAD design drawing.