Automated Measurement of Trilobular (Triangular) Screws

(Desktop Type; TIMI_F)

Automated Measurement of Trilobular (Triangular) Screws

Application Overview

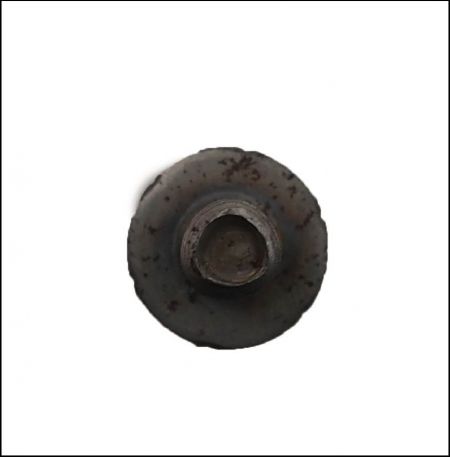

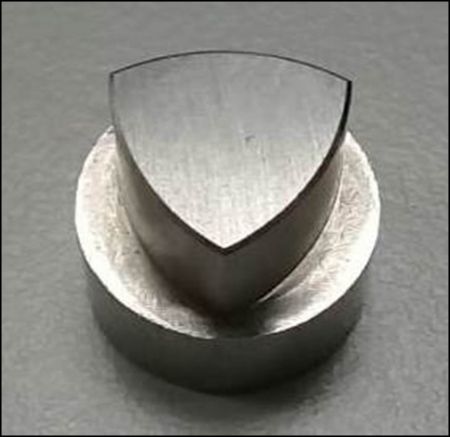

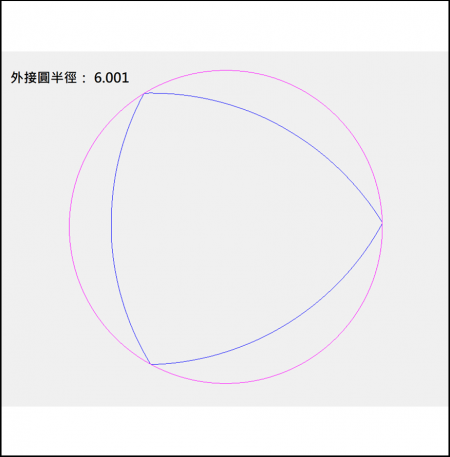

In triangular or trilobular screw designs, the C/D ratio—defined as the inner diameter (C) to outer diameter (D) of the thread—is a critical metric that directly impacts the screw’s fastening performance, torque stability, and assembly reliability. If the ratio deviates beyond tolerance, it may cause thread interference, inconsistent locking, or assembly failures.

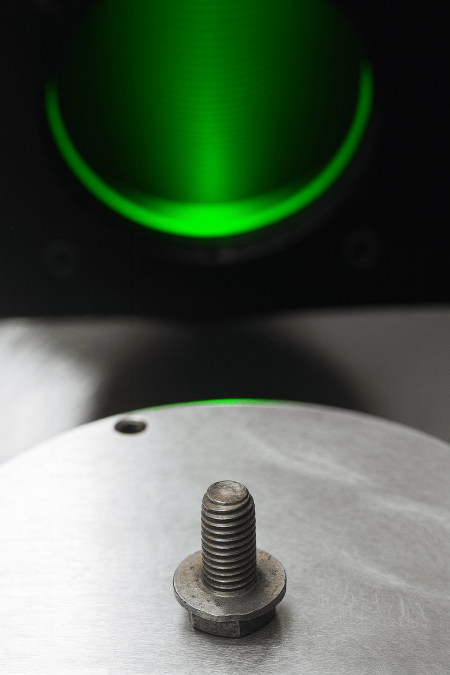

To address this, the AI Thread Detection Expert System, integrated into the TIMI_F desktop-type telecentric image measuring instrument, enables high-speed, high-accuracy measurement of trilobular screw dimensions. This system automates the detection of C and D values, as well as thread concentricity, ensuring precision and consistency in high-volume manufacturing or quality control settings.

Inspection Challenges

- Trilobular screws are asymmetric by design, making traditional rotational alignment and measurement tools (e.g., V-micrometers) slow and error-prone

- Accurate measurement of C/D/E values requires full 360° profile scanning, which is difficult with contact-based tools

- Manual placement and alignment increase the risk of measurement variability and operator error

- Standard inspection methods often cannot verify concentricity in asymmetrical screw profiles

- Manufacturers require faster, automated tools that support inline or near-line dimensional inspection

Solution

The TIMI_F desktop-type telecentric image measurement system offers a non-contact, fully automated solution specifically designed for trilobular screws. It uses rotational imaging to inspect the complete screw profile and calculate C/D/E values and concentricity, without requiring precise alignment or manual centering.

Key Features:- 360° automatic rotational scanning of trilobular screws

- No need for manual alignment — accurate C and D value measurement without centering

- Detects imperfect or irregular triangular shapes with precision

- Automatically measures thread concentricity

- Desktop format — compact and suitable for laboratories or production environments

- Currently the only image measurement system on the market that can automatically measure trilobular screws

- Significantly reduces reliance on traditional V-micrometers and eliminates manual variability

- Enhances product consistency and dimensional traceability

- Speeds up quality control — each screw can be inspected in seconds

- Suitable for high-mix, high-volume fastener production requiring tight quality standards

- Supports real-time data output and report generation for quality assurance and compliance

- Measurment Application

Desktop Image Measuring Machine

DetailsDesktop Image Inspection Machine is suitable for measuring shaft, screw & cylindrical parts: outer dia ≦ 60mm;L≦ 100mm, ≦ 200mm (TIMI12F/ 30F/ 40F / 60F)

- Video