Moters & Appliance Parts Measurement

Application Background

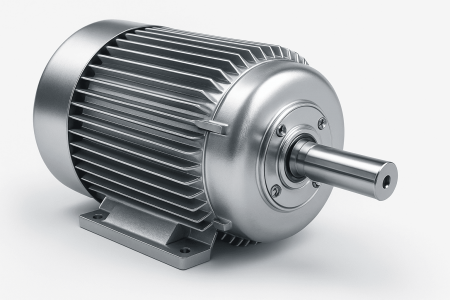

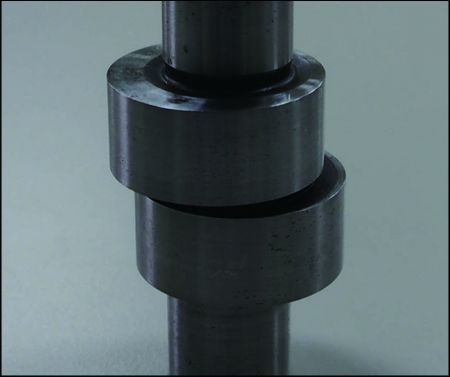

In motors and compressors, shaft precision directly impacts the performance, efficiency, and lifespan. Motor shafts require precise control of grinding outer diameter, segment height and runout due to their high-speed design. Compressor crankshafts feature complex geometries that require more advanced measurement, including Roundness, Cylindricity and Coaxiality. However, traditional contact tools and CMMs are slow, labor-intensive, and unsuitable for high-volume inline inspection.

Common Measurement Challenges

- High accuracy requirements are limited by operator variability in manual measurement

- Complex crankshaft geometries are difficult to measure with contact tools

- CMMs are lab-based and cannot provide real-time process feedback

- Manual record-keeping leads to traceability and data analysis issues

- Inline full inspection demands are hard to meet with conventional tools

Solutions & Technical Advantages

- Motor Shaft: OD, segment height, runout

- Compressor Crankshaft: Roundness, Cylindricity and Coaxiality

- Full dimensional inspection in one rotation

- Telecentric lens + high-resolution algorithm for complex, multi-segment geometry

- Robotic integration for automatic loading/unloading

- Real-time data visualization and SPC analytics

Key Benefits

- 5–10× faster shaft inspection; full analysis completed in seconds

- Automated measurement of complex crankshafts reduces manual errors

- Real-time reporting enables process control and continuous improvement

- Scalable integration with ERP/MES systems supports digital transformation

- Reduced labor costs, simplified operation, and shorter training time

Online Full Inspection of Motor Shaft Dimensions

(Centering-Type: TIMI_P ;Cabinet-Type: TIMI_A)

TIMI-series automatically measure full- dimensions in 20 seconds. Measurement results are automatically...

DetailsMeasurement of Oil Pump spindle

(Precision-Type: TIMI 30P/ 40P)

TIMI-system measures the oil pump spindle 5 to 10 times faster than using a contact probe....

DetailsMeasurement of Punch Heads

(Auto-Type; TIMI 30A/ 40A)

Hundreds of punch heads can be inspected in one hour. It can be used in mass production inspection...

Details

Industry_motor.png?v=af99161b)