Driveshaft & Ball Screw Measurement

Application Background

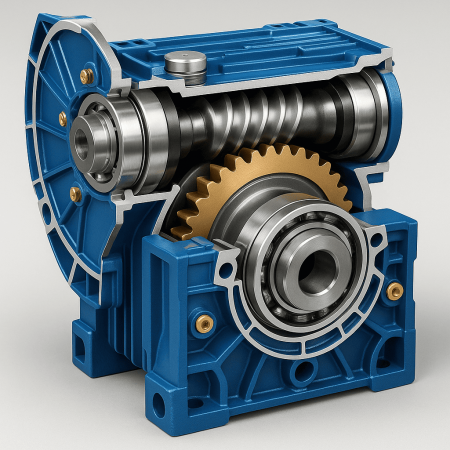

Ball screw accuracy directly impacts power transmission, machining precision, and equipment lifespan. Traditionally, only a few dimensions were sampled in the lab using length gauges. Likewise, worm shafts in reducers are typically inspected with contact-type gear testers—time-consuming, operator-dependent, and limited in accuracy. As precision and efficiency demands increase, manufacturers need inline, high-accuracy, automated solutions to ensure consistent quality and improve yield.

Common Challenges

- Long, slender parts deform easily during manual measurement

- Complex features like threads require multiple tools and setups

- Lab-based inspection disrupts production flow

- Manual operations and records risk data loss and traceability gaps

Solution & Technical Advantages

- Non-contact imaging for full-size, high-speed inspection

- Rotary stage enables multi-angle scans for profile and geometry capture

- Supports segmented measurements for threads, grooves, and shaft steps

- Advanced edge detection ensures high resolution and repeatability

- Integrated with SPC/ERP for real-time QC reports and alerts

- Compatible with robotic systems for automated loading and 100% inspection

Key Benefits

- 5–10× faster than traditional methods

- Real-time visualization and reporting for faster quality decisions

- Simplified training and operation for on-site use

- Reduced human error, improved first-pass yield

- Fully supports automation and full-line inspection

Measurement of Automobile Transmission Shaft

( Centering-Type: TIMI_P)

The Precision-type Measuring Machine is perfect for the transmission shaft measurement of outer...

DetailsMeasurement of Automobile Cam Shaft

( Centering-Type: TIMI_P)

The Precision type Measuring Machine is the best for the shaft measurement of outer diameter,...

DetailsMeasurement of Motorcycle Transmission Shaft

( Centering-Type: TIMI_P)

Multiple measurement functions have been integrated into one machine. It can complete the full-dimension...

Details

Industry_ballscrew.png?v=307f72f2)

.jpg?v=34b537d3)