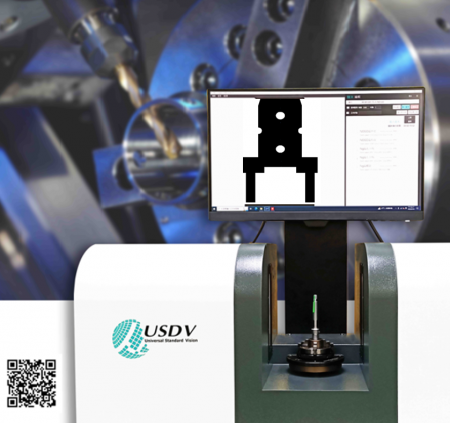

Optical & Electronic Component Measurement

Application Background

With the rise of high-speed communications, 5G, and photonic integration, dimensional accuracy in optical and electronic components has become increasingly critical. Non-ferrous connectors made of stainless steel, copper, or aluminum are often small and soft—prone to scratching or deformation when measured with traditional contact probes. USDV’s tele-centric image TIMI system provides fast, automated measurement without damage. It accurately analyzes contours composed of arcs and lines using tele-centric imaging—up to 50× faster than conventional lab methods—offering a precise, non-destructive, and high-throughput inline inspection solution.

Common Challenges

- Tiny, complex parts are difficult to measure with contact probes

- Chamfers and curved transitions can't be captured with a single tool

- Long inspection times and no real-time data visibility

- High-value parts are costly to scrap due to measurement errors

- Manual tools (microscopes/projectors) lack traceability and are labor-intensive

Solution & Advantages

- Supports ø1mm–ø40mm micro components

- Precision contour analysis: roundness, curvature deviation, auto-fit baseline

- Non-contact to prevent scratches and accumulated errors

- Robotic loading support for inline batch inspection

- Integrated SPC reports, GO/NG judgment, ERP connectivity

- Optional high-magnification optics and micro fixturing for ultra-small parts

Key Benefits

- Measures complex contours and multi-segment profiles with high precision

- 10–30 second cycle time, over 50× faster than traditional methods

- Real-time SPC and visual reports for fast process control

- Scalable for full automation and smart manufacturing systems

Axle measurement of 5G/3C device

(Precision-Type:TIMI 12P/ 30P; Auto-Type: TIMI 12A/ 30A)

The tiny turning axle is often milled in different angle dimensions. The measurement of more...

DetailsAxle measurement of optoelectronic device

(Precision-Type:TIMI 12P /30P ; Auto- Type:TIMI 12A /30A)

Virtual measurement technology allows the axle of the optoelectronic device to be easily and precisely...

Details