Screw & Precision tool Measurement

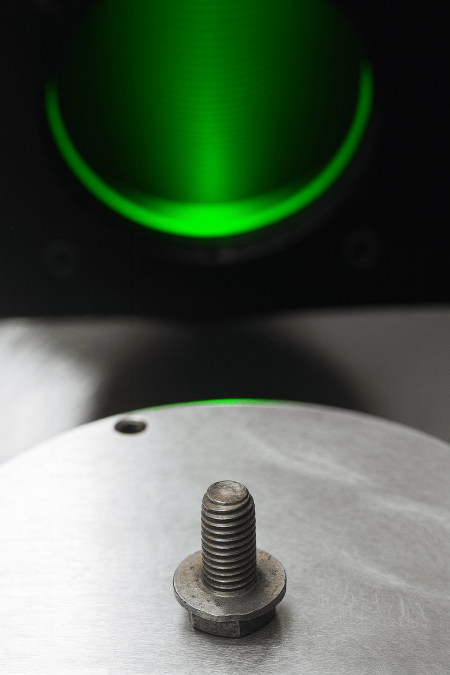

TIMI telecentric imaging systems, combined with a rotary positioning platform and high-precision image algorithms, enable fast, automated thread inspection and concentricity analysis. Designed for high-grade screws and precision threaded components, TIMI significantly reduces quality risks caused by dimensional errors.

Common Challenges

- Traditional tools cannot accurately or efficiently measure C/D/E thread parameters

- Manual inspection is time-consuming and prone to operator bias

- Concentricity between thread and shaft requires rotary measurement, which contact gauges cannot reliably handle

- Lack of automatic recording and evaluation limits full inspection and traceability

Solution & Technical Advantages

- Automatic calculation of C (root width), D (thread angle), and E (effective pitch)

- Rotary platform enables concentricity and effective diameter analysis of threads and heads

- Integrated SPC reporting supports high-volume automated inspection

Key Benefits

- One-pass measurement reduces setup time and tool changes; 5–10× faster than traditional methods

- High-precision profile analysis ensures accurate C/D/E values for quality assurance

- Automated data logging with MES/ERP connectivity enables digital process control

- Supports inline automation, improving yield and reducing scrap and human error

Measurement of Construction / Furniture Fasteners

TIMI-series measuring machine measure the slope and bending degree of screws in a few seconds....

DetailsMeasurement of Standard Fasteners

With Plug-In software of "Automatic Conversion of Standard Screw Measurement Script" ,it is easy...

DetailsSpecial Thread Measurement

Place the screw horizontally and automatically rotate to position the screw angle to measure...

DetailsPitch Diameter Measurement of Thread Plug Gauge

(Precision-Type: TIMI 30P)

Precisely and rapidly measure pitch diameter and compare with standard thread plug gauges....

DetailsMeasurement of Medical Fasteners

(Auto-Type: TIMI 12A / 30A)

Medical fasteners are small in size and require precise measurement, which cannot be met by general...

Details