Measurement Databank for Smart Manufacturing

USDV’s TIMI Measurement databank

All TIMI-series image measuring instruments are is built-in with the basic statistical analysis tool. It can display Ẋ and R chart of measurement data in real-time, which is suitable for autonomous inspection of shafts mass production.

Background of the Application

Smart manufacturing is a major trend in the industry. Enterprises need to build a measurement database for the quality management system to effectively manage and analyze the measurement data. In the past, inspectors measured and recorded the data manually. Manual recording of measurement data is time-consuming and prone to transcription error. Currently, a comprehensive measuring system with a built-in databank connecting ERP/MES systems is the trend.

Solution

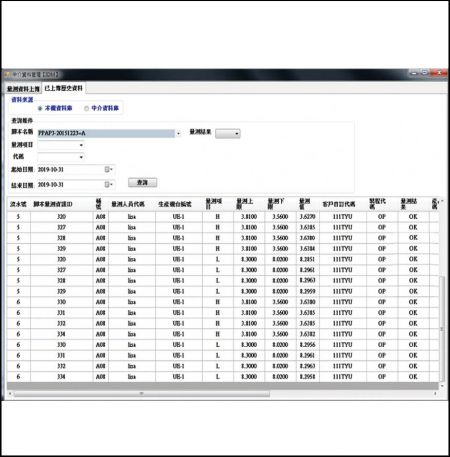

TIMI-series measurement databank is MS-SQL based. All the production control information and measurement data can be exchanged through an intermediary databank which bridging the local database and the client’s ERP/MES system.

Features

1. Download the production control information such as work order, drawing number, measurement script, inspection items, and the upper and lower limits from the client’s ERP system.

2. Feedback measurement data with related product identification code to the intermediary databank.

3. Browse the historical measurement data and analyze it by statistics.

4. Measurement data format is open and is compatible with any ERP/MES/SPC system.

Benefits

After introducing TIMI-series measuring solution for in-process inspection, it is easy to monitor quality control information in real-time by streaming inspection data with the client’s ERP. In the past, the response time for quality correction may be taken several hours. Our measuring solution will shorten the response time of quality correction from hours to minutes. It will greatly improve the efficiency of production. In addition, inspection data stored in the measurement databank can be output for data analysis of smart manufacturing.

- Measurment Application

-

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

DetailsCabinet-Type Image Measuring Machine

Cabinet-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Cabinet-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

DetailsDesktop Image Measuring Machine

DetailsDesktop Image Inspection Machine is suitable for measuring shaft, screw & cylindrical parts: outer dia ≦ 60mm;L≦ 100mm, ≦ 200mm (TIMI12F/ 30F/ 40F / 60F)