Concentricity Measurement of Bicycle Axle

(Precision-Type: TIMI 30P/ 40P; Auto-Type: TIMI 30A/ 40A)

Full-dimension measurement of a pedal axle in 20 seconds.

TIMI-series machines are applicable to the purpose of real-time measurement in the manufacturing process of bicycle axles. They perform size measurements such as outer diameter, arc radius, roundness, and concentricity well with an average cycle time <20 seconds.

Background of the Application

Bicycle shafts like the pedal axle are usually done by CNC turning and grinding. Besides physical dimensions, roundness and concentricity are key inspection items. Using traditional methods or gauges,it will take about 5~6 minutes to inspect and the measurement uncertainty is high. It’s impossible to perform a real-time inspection in the manufacturing process.

Solution

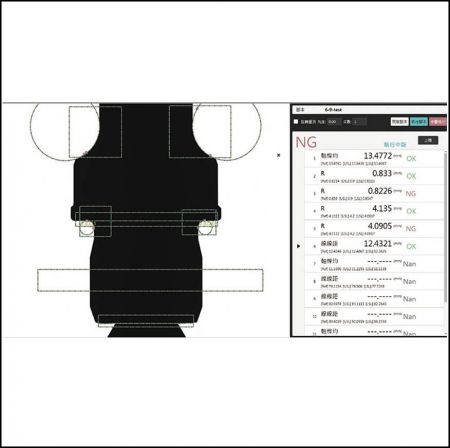

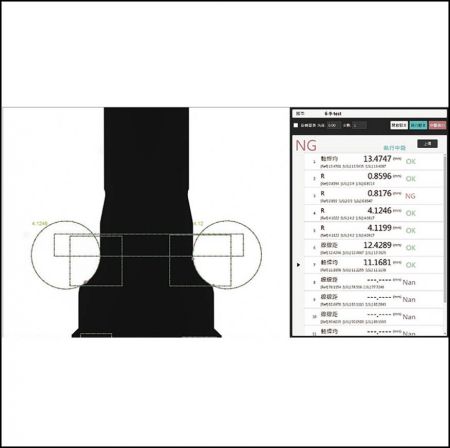

TIMI-series Measuring machines are able to automatically inspect the physical dimensions, roundness, and concentricity of bicycle axles.

Features

Automatically measuring all dimensions of the pedal axle, including outer diameter, arc radius, segment height, and mechanical thread.

TIMI-series machine will automatically detect the central axis coordinate and measure concentricity and roundness without centering.

Benefits

TIMI-machine performs full-dimension measurement of a pedal axle in a cycle-time less than 20 seconds, including outer dimension, R radii, roundness, and concentricity. That is full inspection of a small shaft like a bicycle pedal axle can be completed in one process cycle. So it is suitable for real-time inspection in line.

- Measurment Application

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

DetailsCabinet-Type Image Measuring Machine

Cabinet-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Cabinet-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

Details