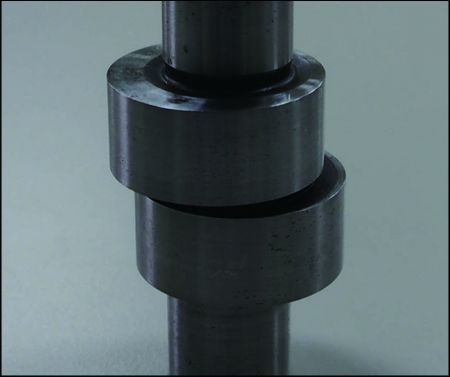

Measurement of Oil Pump spindle

(Precision-Type: TIMI 30P/ 40P)

Physical dimensions of a short shaft and its cam measured in 15 seconds.

TIMI-system measures the oil pump spindle 5 to 10 times faster than using a contact probe. It completes the measurement of the physical dimensions of a short shaft and its cam only in 15 seconds. And the error is less than 3µm.

Background of the Application

The symmetry of the cams of the oil pump spindle is critical to operating efficiency. Currently, CMM or roundness profilometer is the main measuring tool. But the measuring speed is slow, and the instrument is expensive.

Solution

TIMI30P and 40P precision type systems can measure the cams of the pump shaft faster and precise.

Features

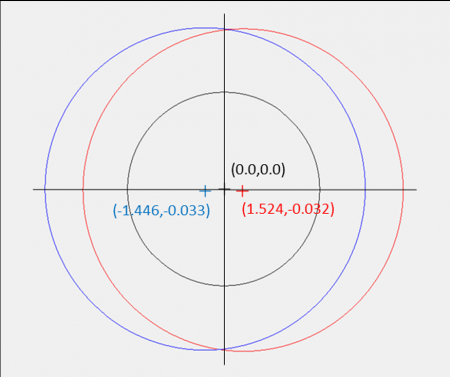

1. Automatically scan the profile of the twin-cam shaft in 15 seconds.

2. Automatically calculate the center coordinates and diameters of the twin-cam shaft. The accuracy is within ±3µm.

Benefits

TIMI 30P or 40P precision type system measures 5~10 times faster than a contact probe.

It takes the advantages of no scratch, high precision, and low equipment maintenance cost.

- Measurment Application

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

DetailsCabinet-Type Image Measuring Machine

Cabinet-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Cabinet-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

Details