Axle measurement of optoelectronic device

(Precision-Type:TIMI 12P /30P ; Auto- Type:TIMI 12A /30A)

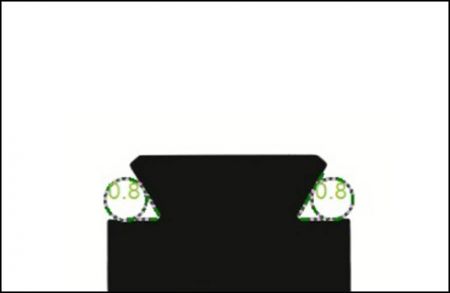

It is simple for axle measurement with auxiliary drawing.

Virtual measurement technology allows the axle of the optoelectronic device to be easily and precisely measured without auxiliary block gauges.

Background of the Application

High magnification images are often used to measure a tiny axle. In order to check the assembling fitness for two components, the measurement has to be facilitated with some auxiliary block gauges, e.x. measuring mechanical thread with a three-wire gauge. It might be a little tough for the purpose of precise measurement.

Solution

Using TIMI-series precision type or automatic type is able to incorporate a physical image with a virtual auxiliary drawing including circle, line, and point for advanced measurements.

Features

The physical image measurement is facilitated with virtual auxiliary drawing.

The virtual auxiliary drawing including circle, line, and the point is incorporated.

Benefits

No need to facilitate with block gauges, the virtual measurement performed by auxiliary drawing allows measurement easy, time-saving, and cost-effective.

- Measurment Application

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

DetailsCabinet-Type Image Measuring Machine

Cabinet-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Cabinet-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

Details