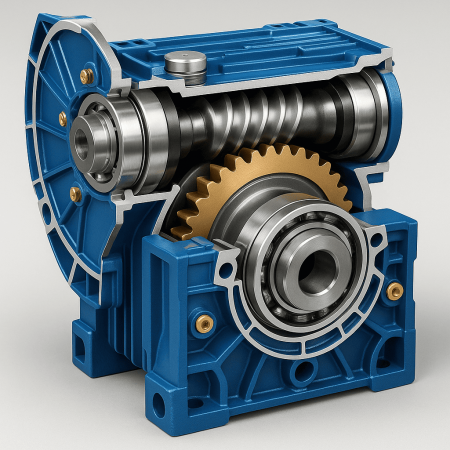

Automated Thread Inspection of Worm Shafts for Gear Reducers

( Centering-Type: TIMI_P)

Precision Thread Inspection for Worm Shafts

Application Overview

Worm shafts are critical components in gear reducer systems and typically feature trapezoidal threads to improve load capacity and contact efficiency. The geometric precision of these threads directly impacts the operating smoothness, transmission efficiency, and noise levels of the gear reducer.

Traditionally, thread inspection has been carried out in laboratories using contact-type gear measurement machines or optical comparators to measure parameters such as outer diameter, pitch diameter, root diameter, flank angle, and pitch. However, these processes are time-consuming, labor-dependent, and unsuitable for real-time process control.

With the implementation of the TIMI Centering-Type Telecentric Imaging System, manufacturers can now automatically measure all critical thread dimensions directly at the production line, enabling immediate in-process quality control and digital record-keeping—greatly improving efficiency and product consistency.

Inspection Challenges

- Traditional contact gear inspection machines are limited to lab use and cannot be integrated into production lines

- Each inspection requires manual adjustment and setup, resulting in low throughput and higher risk of error

- Trapezoidal flank angles and pitch diameters are difficult to evaluate reliably with manual tools

- Lack of real-time data recording and analysis limits traceability and response to quality issues

- Low sampling frequency increases the risk of missing batch-level defects or process drift

Solution & Benefits

The TIMI Centering-Type Telecentric Imaging System provides a fully automated, non-contact solution for worm shaft thread inspection, enabling fast and accurate measurement of all thread-related geometries—making it an ideal quality management tool for modern production lines.

Key Measurement Capabilities:- Outer diameter, pitch diameter, root diameter

- Flank angle (trapezoidal thread)

- Thread pitch and pitch deviation

- Non-contact measurement eliminates tool wear and prevents surface scratches

- Fully automated inspection process completes multiple measurements within seconds

- Supports barcode integration and SPC modules for real-time quality data logging and statistical analysis

- Can be deployed for inline or near-line inspection, or integrated into automated inspection cells

- Enables real-time monitoring of thread dimension variations and early detection of process anomalies

- Reduces manual inspection workload, improving overall productivity and process stability

- Establishes standardized inspection procedures and full traceability, supporting quality audits

- Aligns with smart manufacturing initiatives, enhancing yield rates and overall production competitiveness

- Measurment Application

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

Details