Thread Concentricity Measurement of Bike Fasteners

(Desktop-Type: TIMI_F)

The measuring precision of thread concentricity is ±0.01mm.

Thread Concentricity Inspection for Precision Screw Components

Application Overview

The concentricity of screw threads is a critical parameter that directly influences the tightness, stability, and durability of screw-fastening applications. In high-precision industries such as high-end bicycles or automated assembly, even minor deviations can lead to unstable locking, thread wear, or premature loosening.

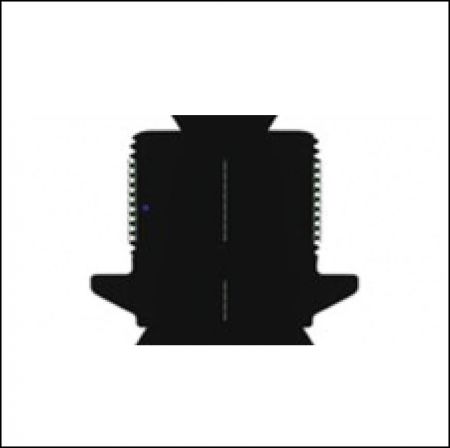

Particularly for cylindrical threaded components, achieving precise concentricity between the thread axis and the screw head is essential. Traditional mechanical methods, such as concentricity meters or dial gauges, often face issues like inaccurate clamping or probe instability on curved thread surfaces.

To address these challenges, the TIMI-series image measurement systems offer a non-contact, high-speed, high-accuracy alternative that is well-suited for inline or near-line inspections in fast-paced production environments.

Inspection Challenges

- Mechanical clamping systems (e.g., concentricity meters) may not hold cylindrical screw heads accurately, leading to false readings

- Probe-based methods often cannot roll smoothly over the threaded surface, causing detection blind spots or measurement inconsistencies

- Tolerances as tight as 0.1–0.2 mm in concentricity are common in high-end fasteners, requiring more precise and repeatable tools

- Manual inspection is slow, inconsistent, and labor-intensive, making it unsuitable for high-volume production lines

Solution

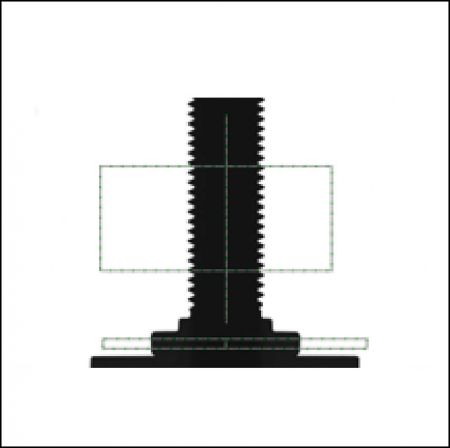

The TIMI desktop series are advanced image measuring machines designed to automatically inspect thread concentricity for small to mid-sized cylindrical screw components. By combining high-resolution telecentric imaging with precision rotary measurement, TIMI enables rapid, repeatable, and contact-free concentricity analysis.

Key Features:- Thread concentricity measurement precision: ±0.01 mm

- Inspection cycle time: only 5–10 seconds per part

- Supports parts with tight tolerance requirements (0.1–0.2 mm)

- Compatible with a wide range of screw sizes and head geometries

- Designed for inline deployment or high-throughput inspection stations

- Non-contact inspection eliminates risk of probe-related surface damage or tool wear

- Achieves high measurement repeatability and traceability, even for complex or lightweight components

- Significantly reduces inspection time and labor costs compared to manual methods

- Ideal for mass production, ensuring every part meets quality and alignment standards before assembly

- Enhances the locking performance, longevity, and safety of screw-fastening applications

- Measurment Application

Desktop Image Measuring Machine

DetailsDesktop Image Inspection Machine is suitable for measuring shaft, screw & cylindrical parts: outer dia ≦ 60mm;L≦ 100mm, ≦ 200mm (TIMI12F/ 30F/ 40F / 60F)