Automated Measurement of Precision Thread Dimensions Gas Cylinder Neck Pitch Diameter

(Type:S-70-60Hybrid)

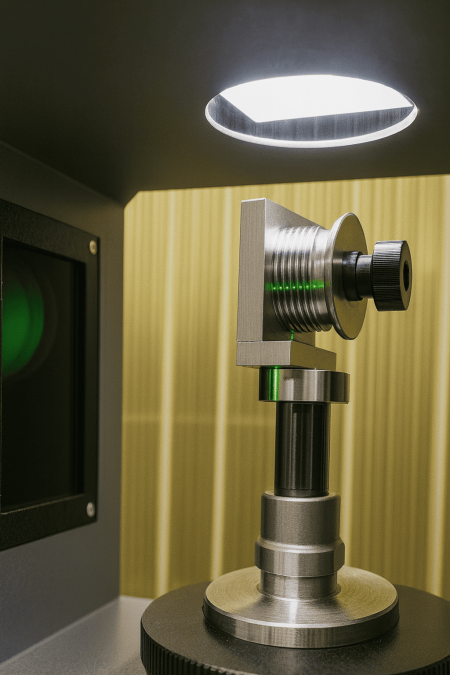

Ultra-Telecentric Imaging Solution for Gas Cylinder Thread Inspection

Solution

To address the dual challenge of large part size and high precision, Usuda Tech developed a proprietary Ultra-Telecentric (UT) Imaging Measurement Technology, which overcomes the limitations of conventional telecentric lenses. This innovation allows micron-level accuracy over wide imaging ranges.

Integrated into the TIMI inspection platform, this solution provides a complete automated measurement system for the pitch diameter of gas cylinder neck threads. It features full image-based inspection, automated reporting, and multi-source data integration—making it ideal for high-throughput, high-reliability production lines.

Key Features:- Uses Ultra-Telecentric imaging technology to double measurement precision for large-diameter components

- Combines backlight and surface illumination to simultaneously measure outer diameter, pitch diameter, minor diameter, and inner diameter

- Supports up to ø60 mm measurement range, with ±3 µm accuracy for pitch diameter

- Integrates high-resolution digital weighing module with a resolution of 0.1 grams

- Accepts data from non-imaging inspection equipment, unified in the TIMI quality database

- Inspects up to 400 cylinders per hour, meeting full inspection requirements for over 100,000 units per month

- Automatically records pitch diameter data and generates reports, enhancing QA systems and audit readiness

- Reduces manual inspection errors and labor costs while increasing measurement speed and consistency

- Builds a fully traceable quality data chain, supporting ISO compliance and smart manufacturing integration

- Resolves precision issues for medium-to-large threaded parts previously unaddressable by standard imaging systems