Dimensional Analysis of Small Turned Contour Profiles

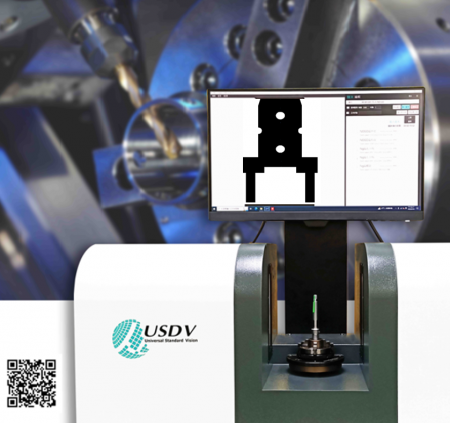

(Desktop Type; TIMI_F)

Contour Profile Inspection for Miniature Turned Parts

Application Overview

In the manufacturing of miniature shafts, connector pins, and optical communication components, the precision of turned contour profiles plays a critical role in ensuring both assembly quality and functional performance. These profiles are typically composed of continuous straight lines and arcs, requiring high-resolution measurement to verify their accuracy.

Traditionally, such geometric profiles are inspected using coordinate measuring machines (CMMs) or form/profile testers in laboratories. However, this process is time-consuming, labor-intensive, and involves transporting parts away from the production line—making it difficult to provide real-time feedback to manufacturing.

Now, with the implementation of the TIMI Desktop Telecentric Imaging Measurement System, contour profiles—including line segments and arcs—can be analyzed directly at the production line. The system delivers results over 50 times faster than traditional laboratory-based methods, greatly enhancing quality control efficiency.

Inspection Challenges

- Traditional profile measuring devices require manual alignment and parameter setup, making them cumbersome

- Contour profiles are combinations of line segments and arcs, which are prone to human interpretation errors

- Measurement must be done offline in laboratories, causing delays in feedback and quality control gaps

- High-frequency sampling and batch traceability are difficult, increasing the risk of overlooking defects

- Lack of digital and automated profile analysis tools limits compatibility with smart manufacturing systems

Solution

The TIMI Desktop Telecentric Imaging Measurement System features high-resolution imaging and automatic geometric recognition, making it capable of precisely identifying the line and arc segments within turned contour profiles. The system automatically calculates critical geometric parameters such as segment length, R angles, arc dimensions, and profile deviation—fully supporting in-process geometric quality control for small precision parts.

Key Features:- Automatic recognition of straight and arc structures in contour profiles

- Measurement items include: step height, R angles, arc radius, etc.

- High-resolution non-contact imaging, ideal for small precision parts

- Real-time inline inspection with cycle time under 20 seconds per part

- Measurement results are automatically stored and exported for quality data analysis

- Replaces traditional CMMs and profile testers, enabling real-time inline quality control

- Fully automated contour analysis reduces human interpretation errors

- Inspection speed increased by more than 50×, supporting large-scale full inspection

- Enhances real-time process feedback, lowering defect risk and scrap losses

- Enables digital quality monitoring and integration with smart manufacturing systems

- Measurment Application

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

DetailsCabinet-Type Image Measuring Machine

Cabinet-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Cabinet-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

Details