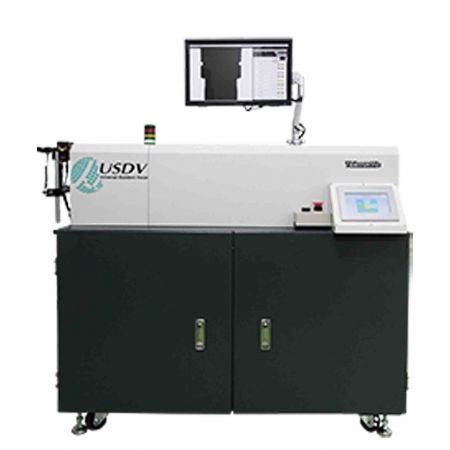

Ultra-Telecentric Image Measuring Machine

Suitable for measuring shafts or cylindrical parts of medium to large size that need for micron-level measurement precision. (TIMI40-40P, S-40-40PH, S-60-20PH, S-70-60Hybrid)

The ultra-telecentric (UT) image measurement technology developed by the USDV can promote measuring...

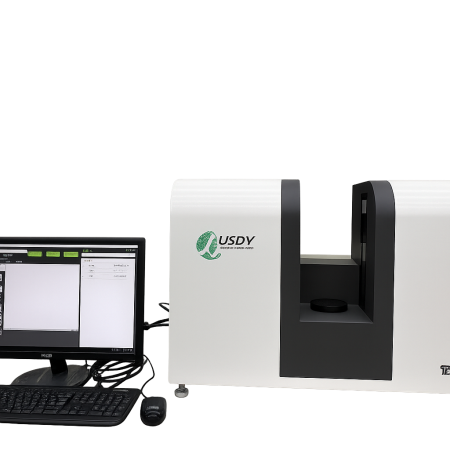

DetailsDesktop Image Measuring Machine

Desktop Image Inspection Machine is suitable for measuring shaft, screw & cylindrical parts: outer dia ≦ 60mm;L≦ 100mm, ≦ 200mm (TIMI12F/ 30F/ 40F / 60F)

Centering-Type Telecentric Image Measuring Machine

(Models: TIMI 60P, TIMI 40P, TIMI 30P)

Looking for a solution to measure longer turned and ground shafts or those requiring high precision?...

DetailsCabinet-Type Image Measuring Machine

Cabinet-Type Image Inspection Machine is suitable for measuring turned parts, screw fasteners, and ground shafts without a center hole. (TIMI 12A,TIMI 30A,TIMI 40A,,TIMI 60A)

The Cabinet-Type Image Measuring Machine can inspect the shaft dimensions of cold-forged, centerless-ground,...

DetailsFlash-Type Image Measuring Machine

The Flash Image Measuring Machine enables rapid measurement without rotation, ideal for fast incoming inspections and on-line production checks. With high-resolution imaging and intelligent recognition algorithms, it delivers precise multi-feature measurements in seconds, reducing manual work and errors. This high-speed, stable solution is designed for modern automated quality control. (TIMI_CE)

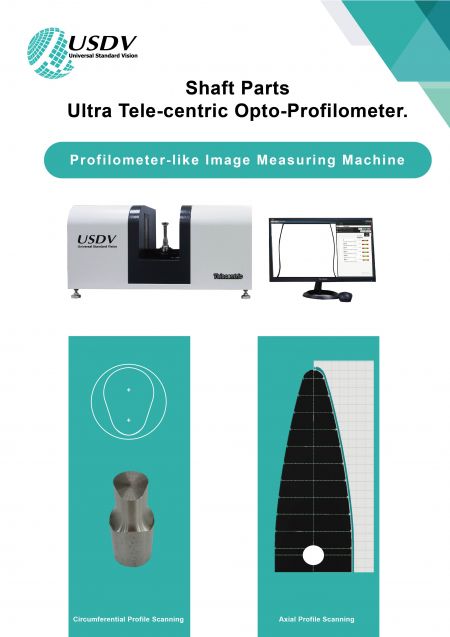

Telecentric Opto-Profilometer for Shaft Parts

A image dimension measurement instrument that can be used as a profile projector This machine...

DetailsMeasurement of Motorcycle CamShaft

(Precision-Type: TIMI 40P, TIMI 100P)

USDV’s Measuring Machine can inspect two cams at once and more than five-time faster than...

DetailsExamples for Shaft Automatic Measurement

1. Hundreds of punch can be inspected in an hour, and the average inspection time for one punch...

DetailsExamples for Screw Automatic Measurement

1. The customer has introduced four units of USDV automated image measuring instruments for use in mass...

DetailsExamples for Screw Automatic Measurement

1. The measurement of pitch diameter of the threaded gauge has an error range of within ±3µm...

Details

.jpg?v=aea3eeb9)